Carburetor tuning involves adjusting the air-fuel mixture to optimize engine performance. Proper tuning ensures efficient fuel delivery and maximizes power. Understanding the basics of carburetor function and the importance of precise adjustments is crucial for achieving optimal results. This guide provides a detailed walkthrough to help you master carburetor tuning effectively.

By following this guide, you’ll learn how to identify and solve common issues, fine-tune your carburetor, and ensure your engine runs smoothly and efficiently. Start your journey to becoming a carburetor tuning expert today!

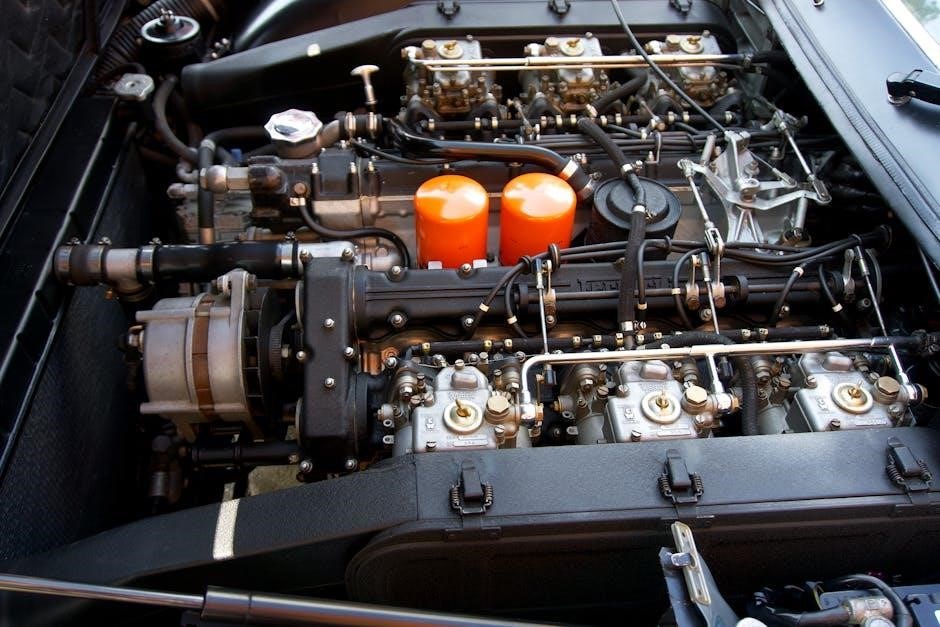

Understanding the Basics of Carburetor Function

A carburetor is a device that mixes air and fuel to create the proper mixture for an internal combustion engine. It operates by using vacuum to draw fuel through a jet into the intake manifold. The throttle controls airflow, while the choke regulates the idle circuit. Proper function relies on the balance between air and fuel delivery. The carburetor’s design ensures that the engine receives the correct mixture at various speeds, from idle to high RPM. Understanding how the throttle, choke, and jets work together is essential for effective tuning. This foundational knowledge helps diagnose issues and optimize performance, ensuring smooth engine operation across all conditions.

By grasping these principles, you can better appreciate the importance of precise adjustments during the tuning process.

Why Proper Tuning is Essential for Performance

Proper carburetor tuning is vital for maximizing engine performance and efficiency. A well-tuned carburetor ensures the right air-fuel mixture, delivering optimal power and responsiveness. Improper tuning can lead to issues such as poor acceleration, reduced fuel efficiency, and increased emissions. By adjusting the air-fuel ratio, idle settings, and other parameters, you can enhance your engine’s overall performance. Additionally, proper tuning helps prevent damage to engine components, ensuring longevity and reliability. Regular tuning is especially important after modifications or changes in operating conditions. Investing time in tuning yields significant benefits, making it a crucial step for any engine setup.

A finely tuned carburetor not only improves performance but also ensures smooth operation across various driving conditions.

Tools and Materials Needed for Carburetor Tuning

Essential tools include screwdrivers, torque wrenches, and cleaning brushes. Materials like gaskets, jets, and fuel filters ensure optimal performance and longevity.

Essential Tools for Adjusting and Cleaning

Proper tools are crucial for effective carburetor tuning. Start with a flathead and Phillips screwdriver for adjusting mixture screws. A torque wrench ensures precise adjustments without over-tightening. Cleaning brushes and compressed air help remove dirt and debris. An air-fuel mixture gauge aids in precise tuning, while a vacuum gauge checks engine stability. A rebuild kit and replacement jets are handy for fine-tuning. A clean workbench and safety goggles protect you during disassembly. Fuel line testers and carburetor cleaning solutions are also recommended for thorough maintenance. These tools ensure accuracy and safety throughout the tuning process.

Recommended Materials for Optimal Results

High-quality materials are essential for achieving the best outcomes in carburetor tuning. Use precision-crafted jets and needles to ensure accurate fuel delivery. Replace worn-out gaskets and seals to maintain proper vacuum and prevent leaks. Cleaners specifically designed for carburetors effectively remove grime without damaging components. A fuel filter kit ensures clean fuel flow, preventing clogs. Polishing cloths and mild abrasives help restore parts to their original condition. Lastly, always refer to manufacturer specifications for jet sizes and replacement parts. These materials guarantee optimal performance and longevity of your carburetor.

Step-by-Step Carburetor Tuning Process

Start by preparing the carburetor, then adjust the air-fuel mixture and idle settings. Fine-tune for maximum performance, ensuring smooth operation across all RPM ranges.

Preparing the Carburetor for Tuning

Before tuning, ensure the carburetor is clean and free from debris. Remove the air filter and inspect the choke valve. Check for any vacuum leaks and secure all connections. Drain old fuel to prevent contamination. Use a carburetor cleaning kit to remove dirt and varnish from jets and passages. Replace any worn or damaged gaskets and O-rings. If rebuilding, install a fresh rebuild kit with the correct specifications. Once clean and reassembled, attach the carburetor to the engine. Warm up the engine by pulling the choke and allowing it to idle briefly. This ensures the engine is at operating temperature for accurate tuning.

Adjusting Air-Fuel Mixture and Idle Settings

Begin by turning the air-fuel mixture screws counterclockwise to richnessen the mixture. Start with 1-2 turns and test engine performance. Fine-tune by gradually adjusting the screws until the engine runs smoothly. Use a vacuum gauge to identify the optimal setting. Next, adjust the idle screw to maintain a steady RPM. Ensure the choke is fully open and the throttle is at idle. Warm up the engine to operating temperature before making final adjustments. If the engine hesitates or runs rough, slightly enrich the mixture. Properly balanced air-fuel and idle settings ensure efficient combustion and prevent damage to engine components. Always test drive the vehicle after adjustments to confirm optimal performance.

Fine-Tuning for Maximum Performance

Fine-tuning involves precision adjustments to achieve peak engine performance. Use a vacuum gauge to identify the optimal air-fuel mixture, ensuring the highest vacuum reading. Test drive the vehicle at various speeds and loads to assess responsiveness and power delivery. If the engine hesitates or lacks power, slightly enrich the mixture by turning the adjustment screws counterclockwise. For high-RPM performance, adjust the main jet size to deliver additional fuel. Always make small incremental changes and test drive after each adjustment. If backfires occur during deceleration, the mixture may be too rich; Fine-tuning requires patience and careful observation to achieve a smooth, responsive engine operation across the entire RPM range.

Troubleshooting Common Issues

Identify issues like rough idle, poor acceleration, or backfiring. Check for vacuum leaks, dirty jets, or incorrect air-fuel mixture settings. Adjust pilot screws or replace faulty components to resolve problems effectively.

Identifying and Solving Typical Carburetor Problems

Common issues include rough idling, hesitation, or poor acceleration. These often stem from a rich or lean air-fuel mixture. Check for clogged jets or vacuum leaks. Adjust the pilot screws to fine-tune the mixture. If backfiring occurs, it may indicate an overly lean mixture. Cleaning or replacing faulty components like the float or needle valve can resolve issues. Always refer to your carburetor’s specifications for proper adjustment. Regular maintenance ensures optimal performance and prevents recurring problems. By addressing these issues methodically, you can restore your engine’s smooth operation and power delivery effectively.

Safety Tips and Best Practices

Always wear protective gear and ensure the workspace is well-ventilated. Disconnect the battery and use jack stands for stability. Follow proper fuel handling procedures to avoid hazards.

Precautions to Avoid Damage or Injury

When tuning a carburetor, always disconnect the battery and ensure the engine is cool to prevent accidental starts. Wear protective eyewear and gloves to safeguard against fuel splashes or tool slippage. Use jack stands for added stability if working under the vehicle. Keep a fire extinguisher nearby, as fuel vapors can be highly flammable. Avoid smoking or using open flames near the workspace. Properly ventilate the area to prevent inhaling harmful fumes. Never bypass safety measures, as they are critical for protecting both you and your equipment. Adhering to these precautions ensures a safe and successful tuning process.

Post-Tuning Checks for Longevity

After tuning your carburetor, perform a thorough inspection to ensure longevity. Test the engine at idle, mid-throttle, and full throttle to confirm smooth operation. Check for vacuum leaks using a carburetor adjustment tool or soap solution. Inspect the air-fuel mixture by monitoring the engine’s performance and exhaust color. Test fuel efficiency and power output to ensure optimal results. Regularly clean or replace the air filter to maintain proper airflow. Inspect the carburetor for wear or damage, especially the gaskets and jets. Store the vehicle in a dry, cool place to prevent rust or corrosion. Schedule periodic tune-ups to maintain peak performance and prevent issues. These post-tuning checks ensure your carburetor remains in excellent condition for years to come.